Poly (Methyl Methacrylate) Microspheres are Used as the Anti-Inhibitors!

When it comes to the use of the transparent thermoplastic, PMMA appears as the first choice. This is also known as polymethyl methacrylate. This material is often considered as the shatter-resistant and light alternative to glass-like material. Due to this reason, sometimes this material is termed as the acrylic glass. From a chemistry perspective, this is nothing but synthetic polymer of the methyl methacrylate. When you are looking for a cost-effective and efficient alternative to PC or polycarbonate like material, the PMMA microparticles will surely appear as the first choice before you. This substance can be used when there is no need for extreme strength. Apart from this, such nanoparticles are not carrying the bisphenol which is a hazardous substance and it can be found easily in polycarbonate.

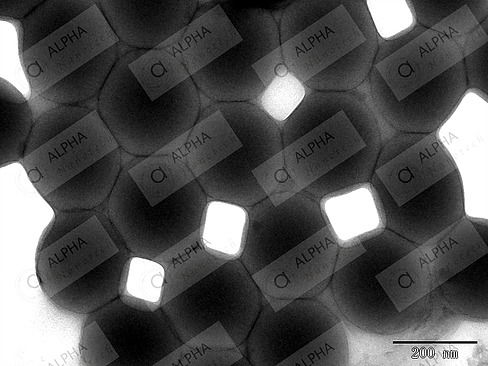

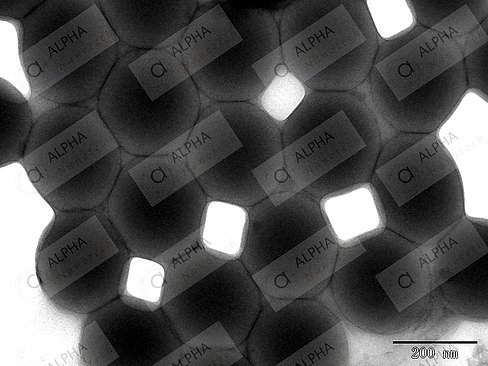

Poly (methyl methacrylate) microspheres

Poly (methyl methacrylate) microspheres

- Used as the matting agent

As far as the poly (methyl methacrylate) microspheres are concerned, they are often preferred for a wide range of applications due to their moderate properties. These microspheres can be handled and processed easily and they are also low in cost. All these properties of PMMA are what making this material the first choice for wide range applications.

- Can behave in a very brittle manner

But there are also some other aspects associated with the PMMA that you should know like these nanoparticles sometimes behave in a very brittle manner. And this occurs when these nanoparticles are loaded or used under a higher impact force. With comparison to the inorganic glass, PMMA has got less resistance against scratch. It is also used as the matting agent when it comes to the making of plastic films and sheet metal.